The International Conference on Extrusion and Benchmark (ICEB)

The International Conference on Extrusion and Benchmark (ICEB) has become the biggest event in Europe related to the recent developments on Extrusion Technology and its analysis by FEM simulation.

The aim of the conference is to join together technical and scientific experts, to widespread their knowledge and to form an international community for the discussion of state of the art, as well as future developments, in the field of extrusion and in its most powerful tool, the numerical simulation. The fifth edition was been held on May 12th-16th 2015 in Florence, Italy.

QuantorForm Ltd. participated in the conference and its extrusion simulation program QForm-Extrusion has shown the best results in metal flow precision accuracy and simulation time against another participating programs.

Scientific Benchmark

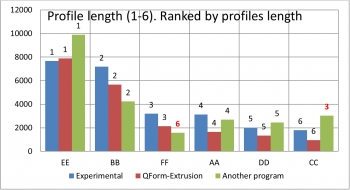

The scientific Benchmark test verified the possibilities of the simulation software to predict the exit velocity from the die orifices. The die had got 6 orifices and material flowed through 6 different bearings. The variation was in the length and choke angle of the bearings. Also they measure the exit temperature of the all rods that exited from the die orifices.

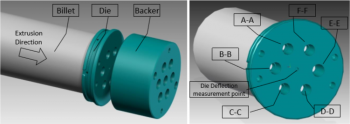

Task of Scientific Benchmark. Left, view of the assembly of die (exploded view) and backer allowing die deflection (central hole is used for die deflection sensor), on the right extrusion die with designation of the six openings

Task of Scientific Benchmark. Left, view of the assembly of die (exploded view) and backer allowing die deflection (central hole is used for die deflection sensor), on the right extrusion die with designation of the six openings

QForm-Extrusion has shown the best results in metal flow precision accuracy and simulation time against other participating programs.

The simulation time in Scientific Benchmark: QForm-Extrusion – 1 hour, Another program – 7 hours.

Industrial benchmark

The main purposes of Industrial Benchmark were to predict final shape of a complicated extruded profile, predict extrusion load, position of seams welds and die temperature.

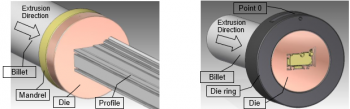

Task of Industrial Benchmark. View of the assembly of billet, mandrel, die and die ring

Task of Industrial Benchmark. View of the assembly of billet, mandrel, die and die ring

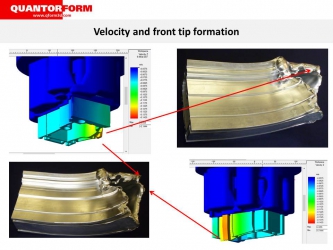

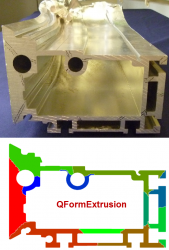

Picture below shows that results in QForm-Extrusion exactly the same as in real.

Comparison of the results of simulation and experimental

Comparison of the results of simulation and experimental

And finally QForm-Extrusion predicts exactly the same as in real seem welds location.

Comparison of seams welds position

Comparison of seams welds position

The simulation time in Industrial Benchmark: QForm-Extrusion – 10 hours, Another program – 83 hours.