Open die forging

Simulation of open die forging in QFormOpen die forging is used for large and critical products which cannot be forged by basic forging processes due to high deformation load or massive dimensions. Technological processes of open die forging are applied to produce individual, low-volume parts for die blocks, rings for further rolling, blanks of crankshafts for marine engines and other large parts requiring the characteristics and durability of a forging. Open die forging with flat dies is sometimes used as a preforming operation for further forging steps, for example on a hammer. Open die forging is actually the first forging process that mankind has mastered.

Simulation of open die forging in QFormOpen die forging is used for large and critical products which cannot be forged by basic forging processes due to high deformation load or massive dimensions. Technological processes of open die forging are applied to produce individual, low-volume parts for die blocks, rings for further rolling, blanks of crankshafts for marine engines and other large parts requiring the characteristics and durability of a forging. Open die forging with flat dies is sometimes used as a preforming operation for further forging steps, for example on a hammer. Open die forging is actually the first forging process that mankind has mastered.

Since many open die forgings are huge it was difficult to develop the technological process economically. Forgers used to perform reduced scale size tests (e.g. 1/25 size) and use the engineer’s methods (upper-bound method, glide lines method and others) to develop the technology but these methods were highly inaccurate. Fortunately, these days, modern finite element mesh simulation software can be used to quickly, accurately and inexpensively develop the technological process for open die forgings.

Simulation of open die forging processes in QForm software solves the following technological tasks:

- Stress-strain state calculation and prediction of material flow in full billet volume during execution of forging operations

- Prediction of structure quality after forging of the cast billet and estimation of surfaces and inner defects, thanks to importing of shape and calculated fields from casting simulation software (e.g. Procast, MAGMA)

- Finding optimal shapes for forging tools

- Finding optimal forging regimes: heating, rotation and/or axial movement between blows

- Developing processes and determining requirements of heating between operations

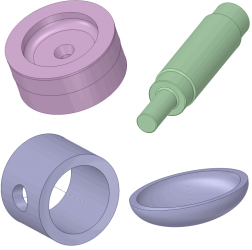

Open die forged parts: the bottom of the hydraulic press cylinder, rotor, casing and bottom of the nuclear reactor

Open die forged parts: the bottom of the hydraulic press cylinder, rotor, casing and bottom of the nuclear reactor Import of simulation results from ProCAST in QForm: temperature and relative density fields

Import of simulation results from ProCAST in QForm: temperature and relative density fields

An engineer’s experience is not enough for developing such complex technological processes where the workpieces are so large and expensive and the possibility of incorrect process design is high. This is why simulation is necessary for open die forging of large billets (50-300 tons).

Advantages

- Material flow prediction depending on tool shape, rotation and/or axial movement between blows

- Simulation of complicated regimes of heating and cooling, necessity of inter-operation heating

- Calculating thermo-elastic-plastic stresses during heating and cooling to predict the possibility of cracks

- Possibility to predict macro and microstructure on the computer during development of the process

- Possibility to predict changing of axial billet porosity during forging of cast billet

Special QForm features that help simulate open die forging:

- Dual mesh method for fast and accurate simulation of processes with many blows and localized deformation zone

- Convenient table interface to set multi-blow operations: automation of rotation and/or axial movement between blows

- Special model of forging manipulator for easy simulation of manipulator

- Simulation of heat treatment and thermomechanical processing of billet