Hot forging

QForm UK is an indispensable tool for the development of hot bulk forging technological processes. The program allows simulation of metal flow in different dies on any kind of equipment to predict possible defects (non-filling of a die impression, laps, flow-through defect, etc.)

Closed die forging and flashless forging

Closed die forging and flashless forging Forging simulation in QForm

Forging simulation in QForm

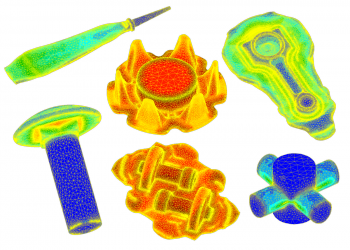

The program shows temperature fields, the stress-strain state indicator in the forging and the tools as well as the fibrous microstructure and other parameters necessary for development of forging technology. The analysis of forging load and energy expended allows the selection of the optimal equipment. QForm UK allows an engineer to optimize the process avoiding defects, decreasing metal consumption and increasing productivity.