Quick Simulation Service

Who else can provide you with simulation and analysis of your metal forming job better than developers of metal forming analysis software and experts with more than 25 years of experience in industrial consulting?

Follow three basic steps below:

1) Send us 3D geometry of the dies and workpiece to [email protected].

2) Send us the technological parameters for each stage of metal forming.

3) Proceed to payment in any convenient way.

Just basic service fee to learn everything about your metal forming technology. It may fall in the following main categories: general metal forming, profile extrusion, cold forming, ring and wheel rolling.

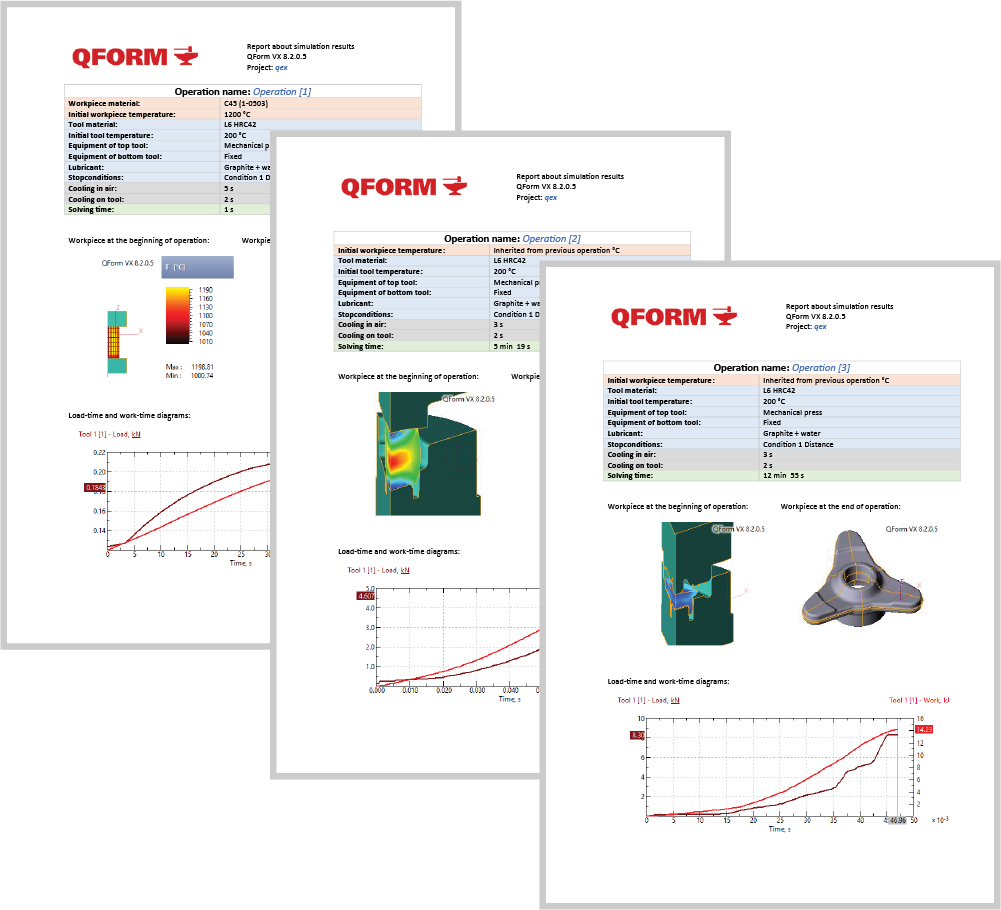

In a few days you receive the professional report prepared by experienced QForm technical support team:

• Detailed metal flow analysis at each stage of a process. Prediction of any kind of defects and underfilled areas.

• Prediction of the maximum force, temperature, strain and stresses distribution in the workpiece and tools. Die life analysis.

The results are presented as a detailed report that includes graphs, pictures and animations with comprehensive explanations. A free webinar can be arranged to provide more detailed explanation of the simulation results and the reasons of technological problems and how to resolve them. Any additional simulation of each project is possible after the correction of initial technology based on the results of the first simulation.