New QExDD features. Closer to real manufacturing

Our new version of QForm-Extrusion Die Designer (QExDD) includes a feature for automated creation of advanced relief in accordance to the specific profile geometry. This feature provides a relief solid model with different offset and inclination values that correspond to the actual manufactured ones. This speeds up the design process, lowers the cost and helps get more accurate 3D models of tooling sets for further extrusion simulation or die manufacturing.

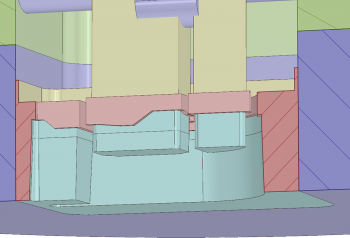

Relief solid model with different offset and inclination values that correspond to the actual manufactured ones

Relief solid model with different offset and inclination values that correspond to the actual manufactured ones

A solid bearings mode has also been added that allows the creation bearings with variable height values in solid models. The bearings are created automatically when they return to the parametrical model according to parameterization in the Bearing editor. Such a model takes the profile geometry characteristics into account and is more suitable for simulation of relief hogging as well as for further manufacturing of tooling set.

Automatically created bearings with variable height values in solid models

Automatically created bearings with variable height values in solid models