New version of QForm VX has been released

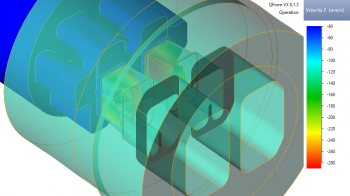

Simulation in QForm of multiprofile extrusion technology. Profile velocity along extrusion direction

Simulation in QForm of multiprofile extrusion technology. Profile velocity along extrusion direction

New version of QForm VX 8.1.3 has been released. This version is the next step of development of QForm VX software which was presented at ET '16 conference in the USA.

Most of the improvements in the new version of QForm VX are focused on the profile extrusion simulation module. New features of this release include:

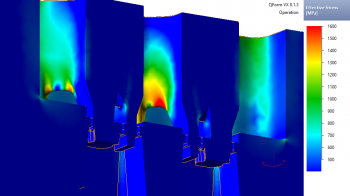

- Coupled simulation of material flow and die deformation

- Simulation of whole billet length extrusion

- Specific interface for extrusion simulation

- Tracking points through container to the extruded profile

- Simulation of longitudinal welding seams (in workpiece fields)

- Simulation of transverse welding seams (in workpiece fields)

- Improved model for calculation of temperature in the die. The temperature is calculated at every step of tool simulation

- Temperature calculation now takes upsetting and die filling into account

- No SHL format for extrusion anymore. Now only QSHAPE format is used for geometry import

- Improved mesh density control in the volume

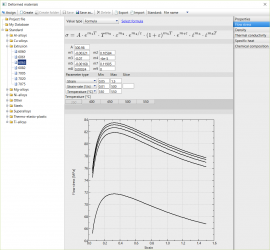

- Completely new deformed material rheology models

- Completely new tool material rheology models

- Interface for setting of die holder, bolster, case and pressure ring temperatures

- Simple interface for indirect extrusion simulation

- An option to specify upset velocity has been added

- New graph for transversal seam weld propagation analysis, i.e the new material share versus the distance from the stop-mark

- Calculation of user subroutines in tracked points

- Velocity gradients tensor was added to parameters of user defined subroutines

- Palettes of temperature and Z-velocity fields scales can be toggled

QForm VX 8.1.3 version obtained a new standard database of billet materials for extrusion simulation. Each of them is a representation of Hensel-Spittel formula to consider properties of material for all possible extrusion conditions. New calculation algorithms together with more accurate material models significantly increase the accuracy of metal flow prediction.

New standard database of billet materials for extrusion simulation

New standard database of billet materials for extrusion simulation Effective stress field in die set. Simulation if QForm

Effective stress field in die set. Simulation if QForm