QForm Forum China overview

The Forum is an event aimed at bringing together representatives of the global professional community — researchers, users, manufacturers, industry professionals, and early-career students — everyone interested in the development of metal forming technologies.

The Forum was attended by more than 70 participants from 50 companies. Attendance figures, a rich program of presentations and the overall atmosphere of the event give every reason to conclude that QForm Forum China was a highly successful event! Start of QForm Forum China 2025

Start of QForm Forum China 2025 General session participants, 26 November 2025

General session participants, 26 November 2025

The key feature of the Forum: how API and machine learning became the main topics of discussion

Nikolay Biba, Director, Micas Simulations Ltd., QForm Group started with statistics on the updates in new version QForm 12. Developments in the fields of API and machine learning became the statistical leaders among the updates. The fact is that today it is impossible to imagine the development of modern simulation and digital manufacturing processes without these technologies.

Which tasks can already be solved with the help of the QForm API?

• Automation of routine operations (automated report generation)

• Data extraction for in-depth analysis

• Process optimization

• Automated process design (QForm Direct, QKaliber)

• Development of machine learning and AI applications

Judging by the audience’s lively response, the number of questions, and the personal discussions, API and machine learning became the central topics of the Forum. QForm 12 new version overview. Smart engineering in metal forming for efficient production by Dr. Nikolay Biba, Director, Micas Simulations Ltd., QForm Group

QForm 12 new version overview. Smart engineering in metal forming for efficient production by Dr. Nikolay Biba, Director, Micas Simulations Ltd., QForm Group QForm and Machine Learning: a new stage in the development of deformation processes by Dr. Nikolay Biba, Director, Micas Simulations Ltd., QForm Group

QForm and Machine Learning: a new stage in the development of deformation processes by Dr. Nikolay Biba, Director, Micas Simulations Ltd., QForm Group

One of the key presentations was given by Ph.D. Artem Alimov, Research Associate, Chair of Hybrid Manufacturing, BTU Cottbus-Senftenberg. The focus was on the analysis of uncertainties in hot bulk forging using automated finite element calculations via API.

The practical continuation of this topic was presented in the talk by Igor Alimov, an engineer at the QForm Group Longitudinal Rolling Department Bureau, titled “How to Use the QForm API to Save Resources in Routine Operations?” Here, the API was considered not as a research tool, but as a means of saving time, money, and human resources.

In the presentation by Dr. Nikolay Biba, Director of Micas Simulations Ltd., QForm Group, entitled “QForm and Machine Learning: A New Stage in the Development of Deformation Processes” the discussion moved to the next level — the use of machine learning to predict and optimize deformation processes. QForm 12 new version overview. Smart engineering in metal forming for efficient production by Dr. Nikolay Biba, Director, Micas Simulations Ltd., QForm Group

QForm 12 new version overview. Smart engineering in metal forming for efficient production by Dr. Nikolay Biba, Director, Micas Simulations Ltd., QForm Group Smart Forming: Advanced simulation technologies for process design in the production of semi-finished copper products by Dr.-Ing. Hendrik Busch, Head of Technology and Development, KME Mansfeld GmbH

Smart Forming: Advanced simulation technologies for process design in the production of semi-finished copper products by Dr.-Ing. Hendrik Busch, Head of Technology and Development, KME Mansfeld GmbH

Where practice builds trust: how real manufacturing confirmed the value of QForm

A separate and highly important track of the Forum was dedicated to presentations on the practical application of QForm in real manufacturing.

The confirmation of this was the presentation by Dr.-Ing. Hendrik Busch, Head of Technology and Development, KME Mansfeld GmbH. — “Smart Forming: Advanced simulation technologies for process design in the production of semi-finished copper products” — complex and demanding materials which require highly precise control of deformation.

Uncertainty analysis in hot bulk forging using automated API-driven finite element simulations by Ph.D. Artem Alimov, Research Associate, Chair of Hybrid Manufacturing, BTU Cottbus-Senftenberg

Uncertainty analysis in hot bulk forging using automated API-driven finite element simulations by Ph.D. Artem Alimov, Research Associate, Chair of Hybrid Manufacturing, BTU Cottbus-Senftenberg Advanced Applications of QForm in Extrusion: Die Optimization and Microstructure Evolution by Dr Jiaxin Lv, Research Assistant Professor, The Hong Kong Polytechnic University

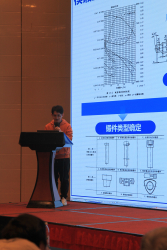

Advanced Applications of QForm in Extrusion: Die Optimization and Microstructure Evolution by Dr Jiaxin Lv, Research Assistant Professor, The Hong Kong Polytechnic University

This was followed by a presentation by Ruxue Liu, Research Associate, Suzhou Laboratory — “Simulating microstructure evolution in extrusion through integration of QForm with a coupled crystal plasticity–cellular automation approach” as well as a talk by Dr Jiaxin Lv, Research Assistant Professor, The Hong Kong Polytechnic University — “Advanced Applications of QForm in Extrusion: Die Optimization and Microstructure Evolution”. These presentations emphasized die optimization and microstructure control in extrusion processes.

Positive user feedback, real-world implementation cases, and an open, honest discussion of both results and challenges — this is exactly how true user trust is built.

More than simulation: QForm Academy as an international educational initiative

The 2025 season of the International Students’ Olympiad on Metal Forming Processes, one of the key projects of QForm Academy, has successfully concluded. During the Forum, we were proud to honor the winner of the national stage, Jiazheng Du, student of Beijing Jiaotong University. We sincerely thank Mr. Jiazheng Du for his participation in the Olympiad and for his inspiring presentation, where he shared valuable insights and tips on how to prepare for the competition.

QForm Academy is a free international educational platform designed to bridge the gap between academic knowledge and industrial application. We offer multilingual webinars, practical training, and collaborative projects to help students gain real-world experience, support researchers in applying their work, and provide enterprises with access to emerging talent and cutting-edge developments.

Hanlong Liu, Beijing Intelligent United Innovation Technology Co. Ltd. awarding the diploma to the Winner of the 2025 National Stage of the Olympiad in China, Jiazheng Du

Hanlong Liu, Beijing Intelligent United Innovation Technology Co. Ltd. awarding the diploma to the Winner of the 2025 National Stage of the Olympiad in China, Jiazheng Du

Three sections, one shared goal

On November 27, the thematic sections began their work:

1 – Forging design, Structure analysis, Sheet forming,

2 – Longitudinal rolling, Ring rolling, Cross rolling,

3 – Extrusion design, Heat treatment, Die life, Quality of profiles.

All participants received training materials and took part in hands-on training under the guidance of our leading specialists.

The sections also featured several standout presentations, providing participants with valuable insights and highlighting the latest advancements in the field.

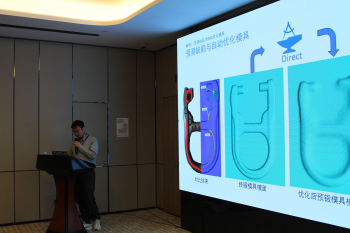

Lukasz Aniol, a rolling expert, presented "Comparative Analysis of Sheet Piles Rolling Methods Using QForm Numerical Simulation – State of the Art Review," providing an in-depth look at current techniques and insights in pile rolling. Guanmei Niu, Senior Engineer at Chinalco Materials Application Research Institute Co. Ltd., presented “Application of QForm in Aluminum Profile Extrusion Production,” showcasing how QForm simulation is applied to optimize aluminum extrusion processes and improve production efficiency. QForm Extrusion Die Designer (QExDD). Fast creation and automated optimization of extrusion tool by Ivan Kulakov, Head of the Metal Extrusion Bureau, QForm Group

QForm Extrusion Die Designer (QExDD). Fast creation and automated optimization of extrusion tool by Ivan Kulakov, Head of the Metal Extrusion Bureau, QForm Group

In conclusion

QForm Forum China 2025 brought together experts, researchers, and students to explore the future of metal forming. From AI and API innovations to real benefit, the Forum showcased how collaboration, education, and technology drive the industry forward. The future of metal forming is digital, intelligent, and shared — and QForm is leading the way.

Special thanks for organizing the event are expressed to the following dream team:

Jiawei Gu, Engineer, Technical Support Department, QForm Group

Evgenia Matykova, Editor at QForm Group

Daria Novikova, Account Manager at QForm Group

Hanlong Liu, Beijing Intelligent United Innovation Technology Co. Ltd.

and Paul Mordvintsev, Business Development Director, QForm Group.