Interviews with participants of International Students Olympiad

In September, the International Student Olympiad on Metal Forming Processes concluded and the results were announced. We contacted the winners and asked them to tell us about their impressions of the competition, share secrets of preparation process, and give advise to future participants.

Follow us: Telegram | Facebook | LinkedIN

"A tsunami of chocolate and a steady stream of coffee kept me focused"

Tayler Samuel Francis, Budapest University of Technology and Economics, Hungary

Hot Bulk Forging section, 1st place

I was born in Hungary in a bilingual family, and I have been living in Budapest since 2020. I graduated from the Budapest University of Technology and Economics in 2024 (following the model curriculum) with a degree in Mechanical Engineering, Material Technology specialization. After one semester of work, I'm now doing a Master’s in Mechanical Engineering Modelling at the same university.

I first started using QForm when I was doing my assignment for one of my subjects on forming technologies. This was during the fifth semester of my bachelor course (2022/2023/1).

I had several options for how I could complete my assignment in the above subject, and one of them was to design a drop forging tool. The added benefit was that we had the opportunity to enter and practice for the QForm Olympiad. I thought it would be a good way to familiarise myself with another FEM program and gain experience.

Of course, the competition was very intimidating at first, as it was the first time during my time at university that I was competing in such a grand event, but with training, I gradually got used to the idea of competing.

When I first heard that the competition would last six hours, it sounded like a lot of time, but it's not. I have prepared myself in such a way that I can do my technical calculations in as little time as possible (a rough estimate would be 20 minutes). The biggest time factor in the whole competition, in my opinion, is how efficiently you can use your chosen CAD programme.

My report took about a quarter of my time, which I tried to do in parallel with all the other steps.

I competed for the first time in 2023 and then I practiced more hours than I can quantify at the moment for the competition. A few weeks before the QForm Olympiad I was practicing almost every day, about 4 hours a day. I made a mistake in my preparation because I overemphasised the efficiency of using CAD and FEM programs, which is why I got third place in the national part.

For my second attempt I've practiced much less, but now I've concentrated on the peculiarities of the workpieces and how to avoid/correct mistakes.

All in all, my biggest help was my mentor, Dr Pál Nyulász, who worked tirelessly with us throughout the preparation process. He gave us all the knowledge that could help us in our endeavor. For my first attempt at the competition, it helped a little to look at what other competitors had done, but not much. For the second attempt, I didn't look at them, except for last year's winner's documentation.

A tsunami of chocolate and a steady stream of coffee kept me focused.

Advise for next year participants: trying to avoid small, careless mistakes, wasting time and energy.

You will have to make many, many changes to the geometry, so be as proficient as possible in CAD! Use a variety of design tricks and methods to build your geometry model. Be prepared to export/import all kinds of files, be careful with coordinate systems and don't waste time aligning tools and materials in the FEM!

"Good luck and believe in yourself!"

Igor Alimov, master's student at Bauman Moscow State Technical University, Department of Metal Forming Technologies, Russia

Rolling Section, Best Work

Igor Alimov

Igor Alimov

I would like to express my gratitude to, Yuri Gladkov, Ph.D. my academic advisor and a lecturer at the Department of Metal Forming Technologies, who encouraged me to participate in the Olympiad.

At our university, students start learning QForm as early as the third year, which helps a lot in subsequent research work and projects. Section rolling was a new technological process for me, because the department mainly focuses on hot forging and sheet metal stamping. A comprehensive study of section rolling helped me prepare for the Olympiad. I studied literature, types of grooves, standard groove designs, rolling parameter calculations, and theoretical information about the process.

In my opinion, 6 hours is a reasonable amount of time to complete the task. The key is to manage your time well and optimize the simulation to finish the project calculations on time.

The execution of the Olympiad task on section rolling can be divided into the following stages:

- Designing the groove in QKaliber: This is the first step to begin with. Based on the knowledge acquired at the university or from reference literature, you need to achieve the required profile shape according to the technical specifications.

- Next, the technology must be verified through simulation in QForm. It's important to set the calculation and mesh parameters for optimal simulation time. While the project is being simulated, you can work on preparing the report or answering theoretical questions.

- The final stage is the analysis of results and completion of the report. This involves comparing the results obtained in QForm and QKaliber, as well as checking them against the technical specifications.

I think these recommendations will help students next year.

Thank you very much to the organizers for interesting tasks and contribution to the development of technical and technological education. I wish the next participants good luck and believe in themselves!

“To treat the Olympiad as a game and enjoy the process”

Irina Sabirzyanova, Student at Bauman Moscow State Technical University, Department MT6 “Metal Forming Technologies”, Russia

Hot Bulk Forging Section, 2nd place

Irina Sabirzyanova

Irina Sabirzyanova

My scientific supervisor and simulation lecturer, who helped me to prepare for this Olympiad, is Yuri Maystrov. I have been simulating in QForm since the fall of 2023, when we started the mathematical simulation course. To be honest, I did not consider myself ready for the Olympiad. My scientific supervisor insisted on my participation, so I decided to try my skills.

I was very nervous before the Olympiad, I was afraid of letting down the people who believe in me. At some point I just started treating the event like a game, it helped me to relax and enjoy the process.

I decided from the beginning that the most important thing is to calculate the allowances, overlaps and tolerances correctly, so I spent the first half of my time only on this, checking all the calculations. The second part of the time was spent on simulation and processing the results. The report was prepared in parallel with the progress of the work.

Preparation for the Olympiad started when I found out that I was enrolled as a participant, namely about a month before the date of the Olympiad. I used guides on standards, manuals by Semenov E.I. and Storozhev M.V., also I found interesting information on the Internet or asked my supervisor.

I thought it was right to make the structure of the report myself first, as the evaluation criteria include the percentage of anti-plagiarism, and then to look at the winners' reports to make sure that my thoughts were correct.

Six hours to complete a task is a lot, but I was very enthusiastic about it, I really liked what I was doing, so the time flew by and I didn't feel tired at all. And after the coffee break I felt even more energized.

For me personally, the most difficult thing was waiting for the Olympiad and then for the results.

My advice to next year's participants: read the literature, look at the task of previous years, communicate with lecturers, feel free to ask questions.

“Stars were only in the sky and at the QForm Olympiad!”

Anastasia Kondratyeva, MISIS, 2nd year of Master's program

Extrusion Section, 1st place

The study of simulation in QForm began in the 3rd year of education at the Department of Metal Forming. Our lecturers Koshmin A. and S. Kriskovich introduced us to QForm and learned to operate in it.

The topic of my bachelor thesis was related to extrusion, and the scientific supervisor Danilin A. and consultant Danilin V. gave a theoretical basis and talked about the possibility of participation in the Olympiad.

Having studied the reports of the winners of previous years, I decided that now is the right time to try my hand and get new experience.

To prepare for the Olympiad I used various articles on the Internet and students' theses on the topic of extrusion.

In my opinion, the Olympiad assignment is more about creativity and ingenuity, so I spent the least amount of time writing my report and decided to make my tool from scratch. This is a great opportunity for future participants to show themselves. The stars were only in the sky and in the QForm Olympiad!

"To thoroughly prepare, practice with the software, and create a report template ahead of time"

Enis Mumajesi, Politecnico Di Torino, Italy

Rolling Section, Special Prize

Enis Mumajesi

Enis Mumajesi

I recently completed my Bachelor’s in Mechanical Engineering in July 2024 and have commenced my Master’s in the same field. Over the past five months, I have focused extensively on simulation using QForm, particularly in forging, which aligned closely with my Manufacturing Processes course. Before the Olympiad, I experienced typical pre-event nerves, much like those before exams. To stay focused, I minimized distractions and relied on coffee to enhance my concentration. I opted to work on rolling, a topic I had recently studied and was keen to explore further. The transition from theoretical knowledge to practical application in QForm was the most rewarding aspect of the experience. As this was my first time participating in the Rolling section of the Olympiad, I believe I managed my time effectively. However, I recognize areas for improvement, particularly in speeding up calculations while ensuring accuracy.

The report-writing process was time-consuming, taking about an hour and a half as I first needed to conduct the simulation before structuring the report. In future Olympiads, I plan to streamline these aspects for greater efficiency. I prepared for the event over nine days but encountered technical issues with setting up the QKaliber software and sourcing suitable study materials. I relied on articles suggested by a company member and online guides. In hindsight, an earlier setup of QKaliber would have allowed me more practice time, facilitating quicker and more accurate roll pass design. Despite the challenges, including maintaining focus for six hours, my determination and ambition to excel in the Olympiad helped me push through the exhaustion.

My advice to future participants is to thoroughly prepare, practice with the software, and create a report template ahead of time.

I am proud to have participated in the Olympiad and look forward to future involvement. This experience has been professionally enriching, enhancing my skills significantly. I am grateful for the support provided by QForm, which was instrumental in resolving technical issues, and for the professional and helpful communication from the QForm team.

"The key to completing the task on time was undoubtedly prior practice and having access to the right resources, such as standards and manuals"

Jakub Długosz, AGH University of Science and Technology, Poland

Hot Bulk Forging Section, 3rd place

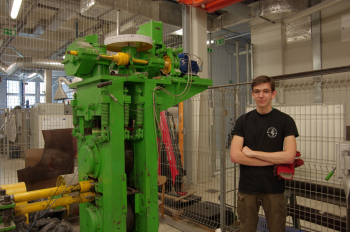

Jakub Długosz

Jakub Długosz

I am a fourth-year student of Metallurgy at AGH University of Science and Technology, on the Faculty of Metals Engineering and Industrial Computer Science. I first encountered the QForm program three years ago during a course organized by my science club, which focused on conducting simulations. The training was led by a winner of one of the previous editions of the Olympiad. Since then, I have used QForm sporadically. When I learned about the opportunity to participate in the competition, I gathered materials such as manuals and standards, and practiced simulations based on tasks from previous editions. The competition itself was quite demanding due to the complexity of the task and the limited time (six hours is not that much). I believe the most challenging part was the final adjustment of the simulation parameters to optimize the process as much as possible. I finished writing the final version of the report just a few minutes before the deadline. The key to completing the task on time was undoubtedly prior practice and having access to the right resources, such as standards and manuals.

“Good luck, believe only in yourself and your powers, and never give up!”

Mikhail Shkolnikov, Verkhnyaya Salda Branch of UrFU, Department of Metal Forming, 2nd year Master's Degree, Russia

Rolling Section, Best Work

Mikhail Shkolnikov

Mikhail Shkolnikov

I would like to express my gratitude to my lecturer Postyliakov Alexander, Phd. of Engineering Sciences, Associate Professor of the Department of "OMD", who prepared me for the Olympiad. I really want to learn how to simulate in QForm, and I decided to test my skills at the Olympiad. The most difficult thing for me was to calculate the tool calibration. I was most worried during the Olympiad, I was afraid I wouldn't be able to complete all the tasks, because calibration calculation and simulation takes a lot of time. The first time I heard about the features of this program was at the university. I take part in this Olympiad for the second time. My bachelor's thesis was on cold rolling of pipes, so I decided to take part in the section of rolling. And for the second time, I decided to keep the section the same in order not to spread myself too thin.

We had to develop the calibration, draw the tool, run the process simulation, as well as answer theoretical questions and solve practical problems.

The calculation of the calibration takes the most time. It is also necessary to set the correct extraction coefficient, to find the right shape of the tool gauge, which will determine the simulation time, the accuracy of the calculation and the shape of the final workpiece, the presence/absence of defects, the amount of chips. After performing this stage, then you need to start the simulation process in QForm, while the process is going on, you should have time to solve theoretical and practical tasks.

A lot of self-improvement work is required in preparation for the Olympiad.

I want to wish the future participants of the Olympiad good luck, to believe only in yourself and your strength, and never give up!

Participation in this Olympiad is a great experience, which will come in handy if you will work with QForm in the future and will study of the metal forming processes.

The International Student Olympiad is an educational project of QForm Academy. The Olympiad is held annually in spring and covers about 14 countries and more than 40 universities. Read how the Olympiad was held in 2024 and 2023 at the link. If you have any questions about participation, please contact [email protected].