2019 – present

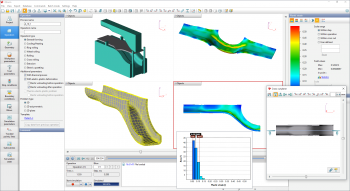

QForm 9 Interface

QForm 9 Interface2019: QForm 9. Find and fix defects quickly with QForm’s new simulation tools

The latest version of QForm has new features and tools designed to allow users to instantly identify and fix forming defects such as flow through defects and cold shuts that have been difficult to spot with traditional simulation software. QForm’s intuitive workflow structure combined with the fastest network and client server multi-core and multi-task options allows users to very quickly investigate and solve problems to develop new jobs and enhance existing forming technologies without press trials. Advanced computational features like dual mesh method, fully thermally and mechanically coupled simulations, and an extensive selection of damage criteria for different deformed materials and low cycle fatigue tool failure prediction, open the way to accurate and quick analysis and optimization of the most complex metal forming processes.

QForm includes specialized modules for bulk and flat rolling and cross rolling processes, ring and wheel rolling, extrusion, electric upsetting, heat treatment and microstructure evolution prediction for steels, titanium, aluminum and nickel-based alloys.

New heat treatment and microstructure evolution simulation modules have been implemented in QForm 9 making it possible simulation phase composition, residual stress, residual strain and predicting mechanical properties such as hardness and ultimate tensile strength.

QForm Ring Rolling has got new features: database of ring rolling mills, cylindrical coordinate system and electro-mechanical drive type. Parameters of tool movement of all known ring rolling mills setup is realized now.

Some automation features were added to rolling module: automatic definition of necessary boundary conditions, automatic use of dual mesh algorithm, automatic mesh adaptation in deformation zone.

QForm Extrusion now allows using symmetry condition for fast and accurate simulation of die sets with symmetry. New features have been added: simulation of several billets, analysis of profile contact with die set relief, consideration of gravity effecting material flow, new special fields for extrusion for faster and more accurate technology analysis, new subroutine for tool damage analysis, new subroutine for direct streaking lines analysis, grain size evolution and heat treatment of the extruded profiles.

QForm 9 supports hexahedral finite element mesh and some more new special features to accurately simulate specific processes such as sheet-bulk metal forming. Also, we have improved simulation and meshing algorithms, user interface got plenty of improvements, and we have added some advanced tools for analysis of different technological processes.