QExDD + QForm Extrusion = Extrusion System. Using the two programs together creates a seamless workflow that speeds up development, reduces risk, and delivers more reliable results, benefiting both die makers and extrusion plants.

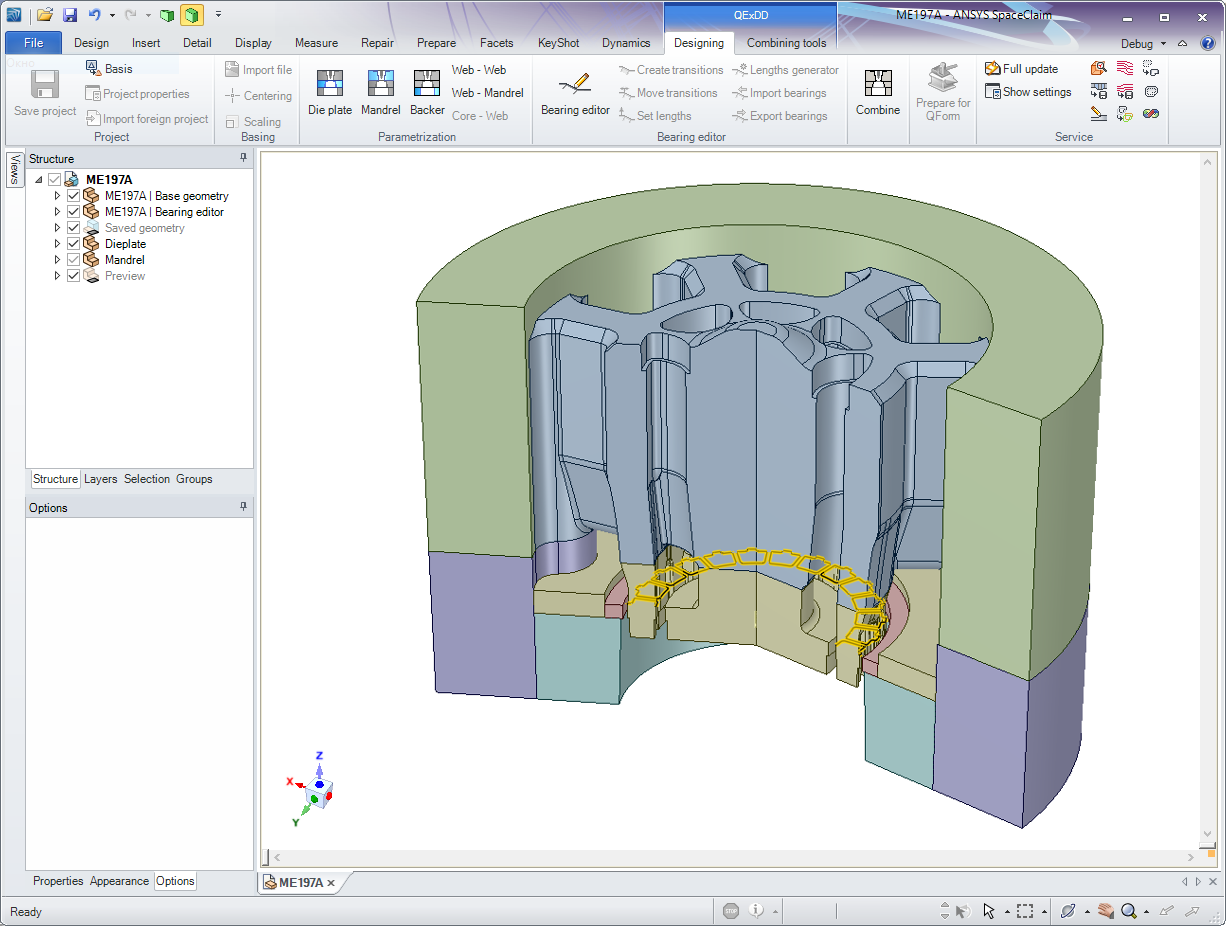

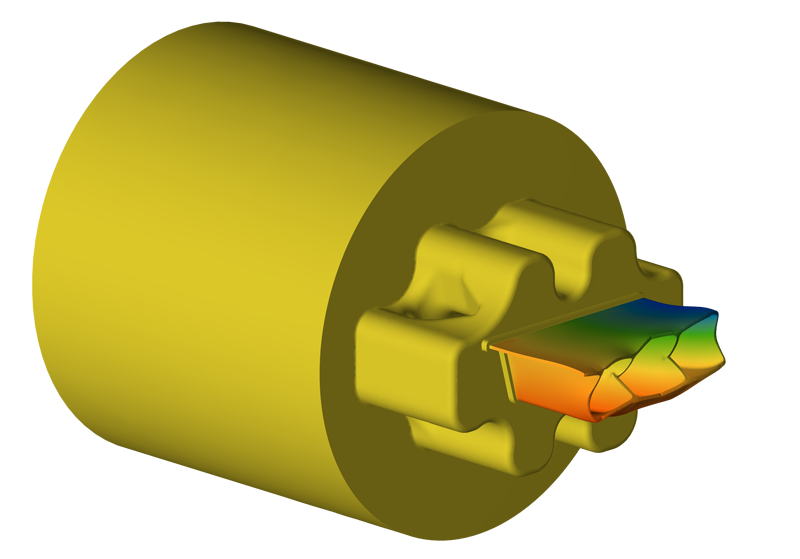

QExDD is an automated system for the 3D creation of dies, mandrels, and other parts of the tooling set for the extrusion of aluminum hollow and solid profiles. This system helps create the solid model of a tooling set step-by-step using special parametric design tools. The user controls the design process by specifying the geometry and basic dimensions of the model. This automated design process is several times faster than conventional die design. Since the routine part of the work is automated by the software, the user can concentrate his attention on more important tasks.

QExDD has been developed as a plug-in to the popular CAD system ANSYS SpaceClaim itself is based on a very effective and novel concept of direct modeling. Thus, the combined use of both QExDD and QForm Extrusion systems significantly increases the productivity of die designers and virtually eliminates the need for die corrections.

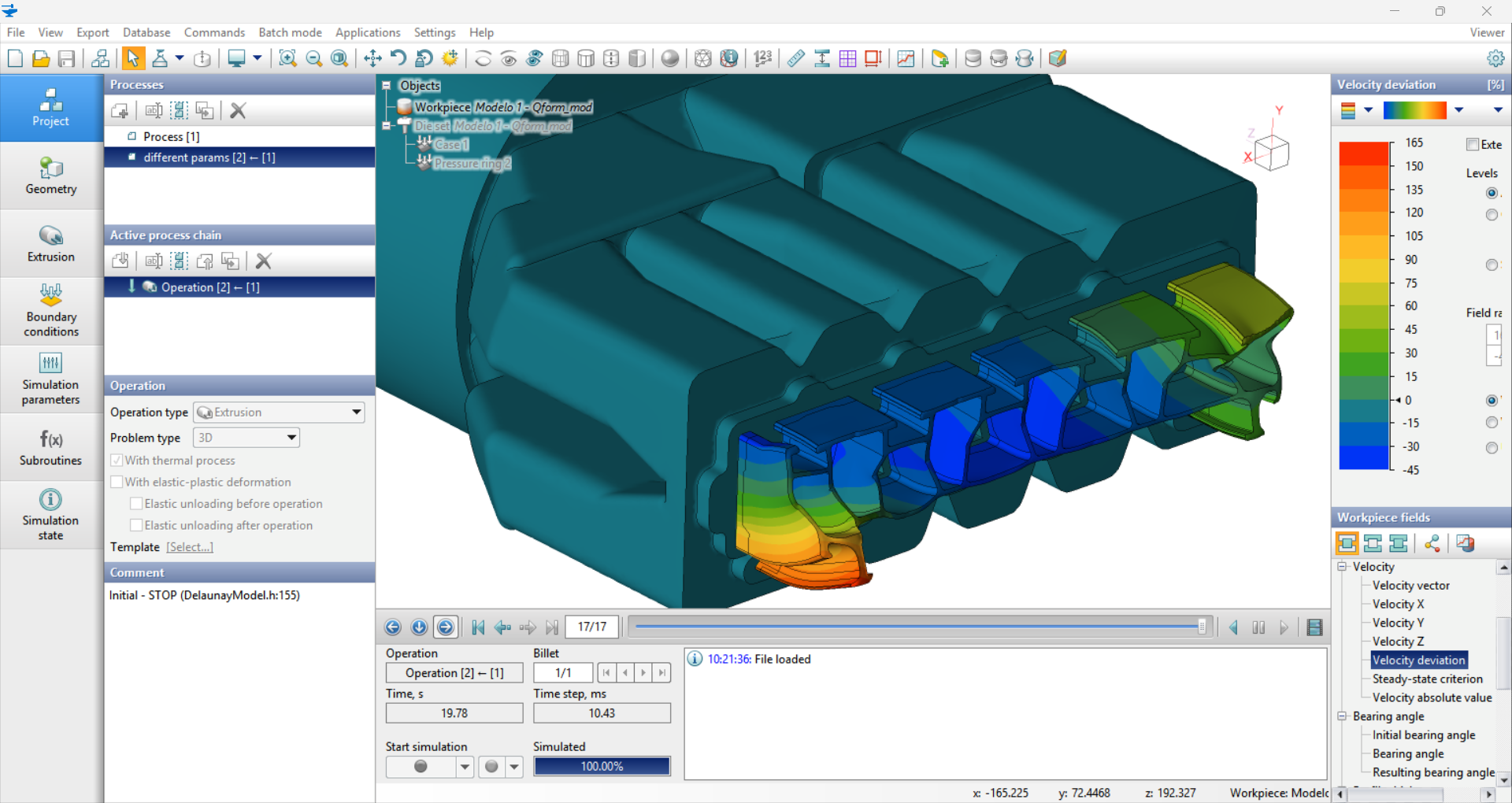

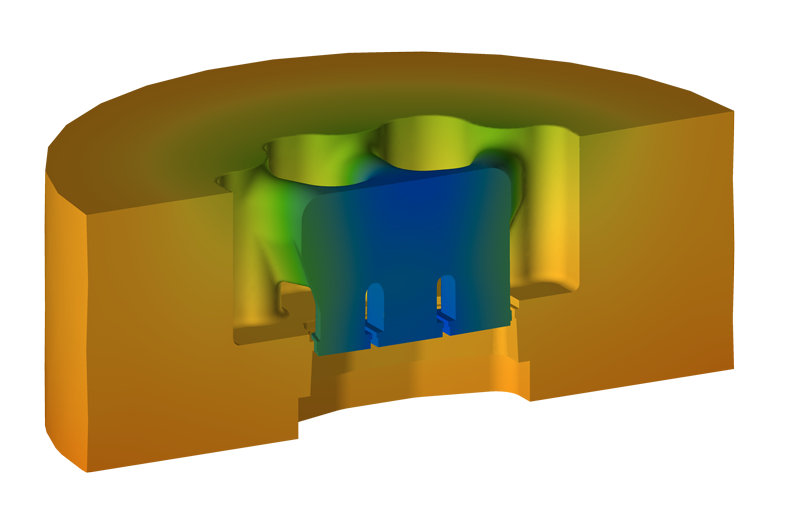

The finite element mesh used for simulation in QForm is automatically created for solid models created in QExDD. To run a simulation of the pressing process, the user only needs to enter process data (e.g. ingot material, ingot and tool temperature, and pressing speed), and the element size and other parameters of the finite element mesh are automatically adjusted.

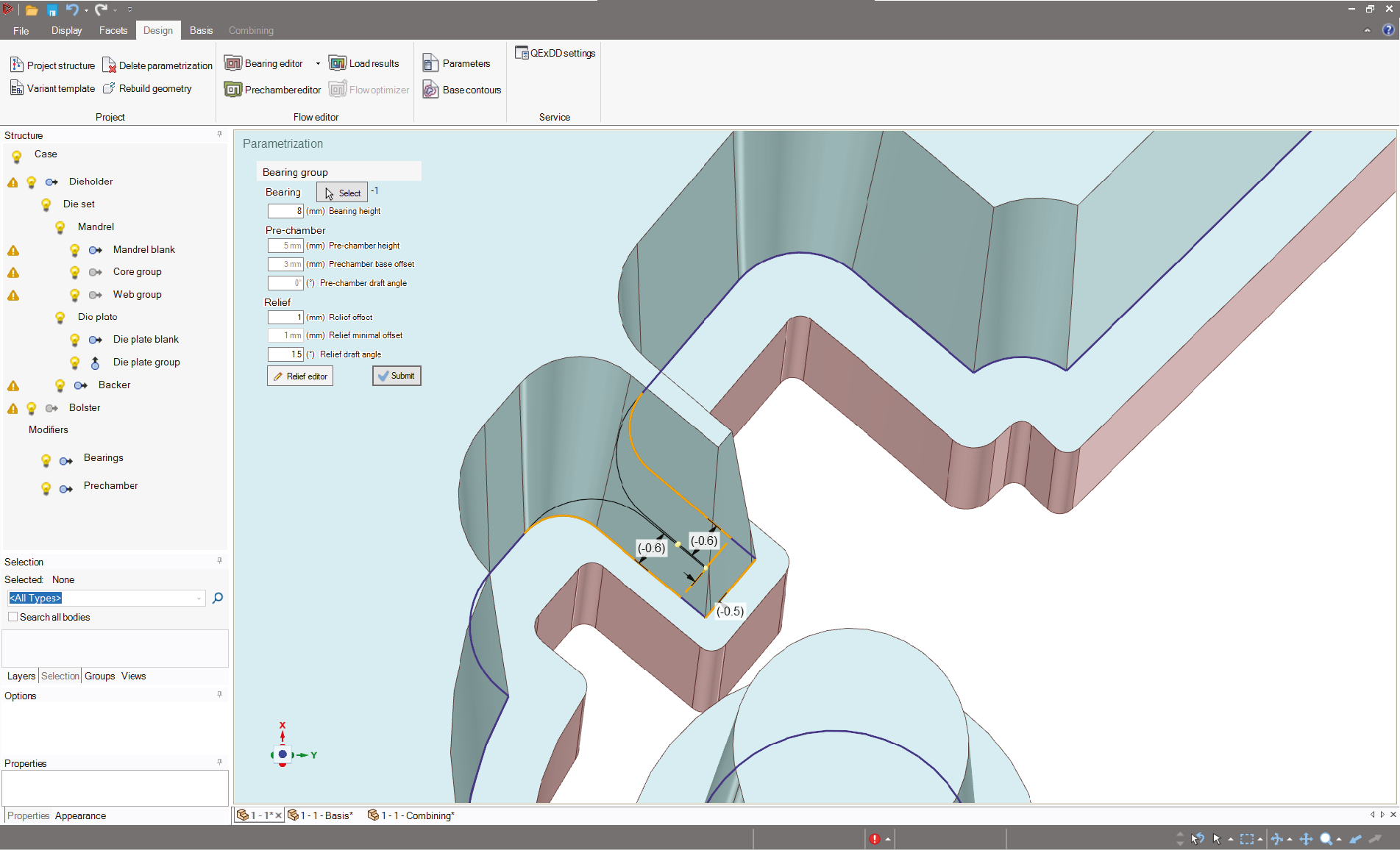

QExDD provides the highest quality solid models that can be used for simulation in our QForm Extrusion simulation program. If the simulation shows some problems with the material flow then any kind of alteration of the die design can be easily implemented in the die model and re-simulated. This makes the simulation and analysis of a designed die set much faster and more effective.

QForm Extrusion is designed to simulate material flow and analyze die stress during the aluminium extrusion process. It features advanced automatic meshing and parametric bearing geometry, allowing precise analysis of small angle variations that can affect flow.

QForm Extrusion is able to consider cases when die deformation causes local zones of very fine inclination of choke or relief that may vary by just a few angular minutes. Simulation results and actual production of our customers as well as laboratory tests have shown that, though small, such bearing angle variation may significantly influence the material flow patterns.

QForm Extrusion has consistently demonstrated its accuracy and reliability by successfully participating in all independent international benchmarks at the International Conference on Extrusion and Benchmark (ICEB) since 2005:

ICEB 2023 – Bologna, Italy

ICEB 2017 – Verona, Italy

ICEB 2015 – Florence, Italy

ICEB 2013 – Dortmund, Germany

ICEB 2011 – Bologna, Italy

ICEB 2009 – Dortmund, Germany

ICEB 2007 – Bologna, Italy

ICEB 2005 – Zurich, Switzerland

The tools for complex extrusion profiles can take a long time to design properly. The use of simulation software significantly speeds up the development time of extrusion tooling, eliminates trials in real press, significantly shorten the time to market, predicts the quality of the extruded product and by these means drastically reduce production cost.

Beyond design and simulation, QForm acts as a hub for collaboration between diemakers and profile manufacturers. By sharing simulation results, both parties gain a deeper understanding, agree on important parameters such as speed and temperature balance, and work together to optimize product quality and process efficiency.

This collaborative approach eliminates the need for costly trial-and-error testing, promotes continuous learning, and raises the overall level of die design and extrusion technology.

Connecting die makers and extruders through smart data. Based on QForm Extrusion simulation software.

QForm Extrusion is an indispensable tool, widely and regularly used by many of the world’s leading die makers and manufacturers of aluminum profiles. The ExtrusionLink concept advances transparent and efficient data exchange between companies and internal departments, enabling users to share virtual simulations and collaboratively improve them.

This breakthrough significantly expands the practical use of simulation in extrusion plants, delivering substantial benefits to both extruders and die makers through improved collaboration, faster optimization, and higher process reliability.

Until recently, the use of simulation by extruders was often limited because, in many cases, the actual 3D digital model of the die could not be shared due to intellectual property restrictions. The new ExtrusionLink concept overcomes this limitation by enabling secure information exchange without exposing proprietary CAD solid files.

The die maker can send to the extruder a special variant of the simulation in QForm Extrusion. In this case, the original solid CAD model of the extrusion die is not shared. Instead, only the simulation project and results.

This guarantees that the die maker’s know-how remains confidential. At the same time, extruders gain complete transparency into die performance and can test the die virtually under different production conditions (extrusion speeds, billet temperatures, surface quality of ingots, etc.) without changing the die geometry.